With the current trend towards digitalization and automation, object handling by robots has become an integral part of the industrial environment. Grippers are the critical interface between the robot and the real world. Typical applications include pick-and-place tasks such as loading and unloading machines, packaging goods, and loading and positioning components for further processing. However, grippers can also perform tasks in the manufacturing process.

Existing gripper systems often require complex adaptations

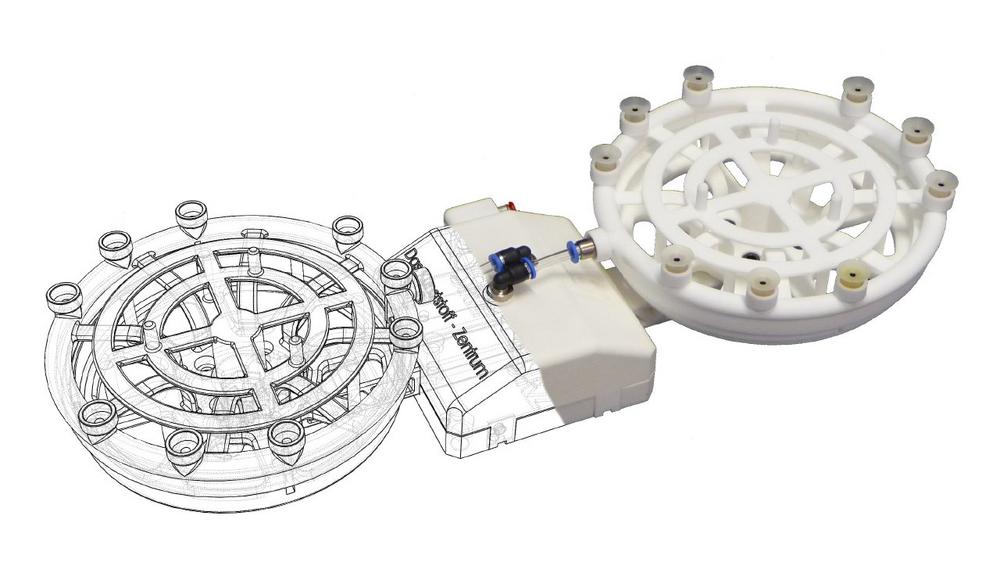

Due to the enormous variety of applications and components, existing gripper systems often have limited applicability or require complex customization. Additive manufacturing technologies are the logical solution. With the right CAD tools and techniques, grippers can be manufactured to fit the application. Thanks to the end-to-end digital process, the path from design to gripper is fast and cost-effective. In addition, standard parts can be reduced, incorporated or designed in, and the gripper can be manufactured and tested before the tool is shipped.

Know-how required – SKZ wants to start here

The only catch is that a certain amount of know-how is required, especially with regard to design rules, in order to avoid falling into an ultimately expensive and inefficient spiral of adaptation. This is exactly where the SKZ wants to start with an industry-funded SKZ pioneer project. The special feature of the SKZ pioneer projects is that they are financed exclusively by the participating industrial companies. The advantage for the participants is an exclusive right to the results and, of course, a significant saving of their own resources. The development work is carried out by SKZ experts in accordance with the jointly agreed requirements of the project participants.

A holistic view of the gripper system

The aim is to optimize the gripper systems, including the development of a design guideline based on best practice applications. The gripper system will be considered holistically, including gripper material, interfaces, gripping mechanisms, control and AF design principles. First, common AF processes will be evaluated for their suitability to produce grippers in order to test the use of appropriate AF materials in the next step (temperature and corrosion resistance, wear, fatigue, etc.). Based on this, AF-suitable designs will be systematically created and tested in practice. At the end of the project, a demonstrator will be available.

SKZ is a member of the Zuse Association. This is an association of independent, industry-oriented research institutions with the goal of improving the performance and competitiveness of industry, especially SMEs, through innovation and networking.

FSKZ e. V.

Friedrich-Bergius-Ring 22

97076 Würzburg

Telefon: +49 931 4104-0

https://www.skz.de

Telefon: +49 (931) 4104-643

E-Mail: k.popp@skz.de

![]()