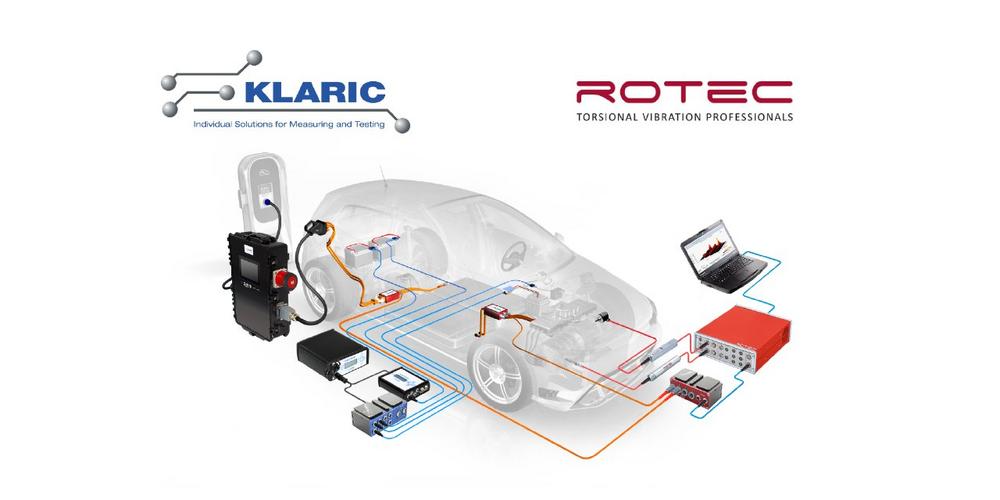

When developing electrified drives, engineers focus on acoustic ride comfort and mechanical loads, among other things. Torsional vibrations cause noise problems in electric motors and transmissions due to mechanical effects and electrical sources. Standard NVH analysis systems use airborne and structure-borne sound signals to investigate the generated noise, vibrations and their transmission paths. However, these usually leave out the mechanism of how these effects are generated. For a detailed and unique cause analysis, Vispiron Rotec with its RASdelta measurement system for torsional and gear analysis, together with Klaric – a measurement technology provider for measuring current and voltage – has developed an integrated measurement and analysis solution for electrical drive trains. It includes measurement and analysis of dynamic torsional vibration, analog measurement variables, CAN/OBD information, current and voltage. The measurement systems are connected via a CAN interface of the RASdelta measurement system. With the KLARIC measurement technology, both motor and regenerative operating modes can be measured. In combination with the ROTEC measurement system for torsion and gear analysis, the correlation between mechanical effects and electrical sources is ensured. Extensive evaluations of the ROTEC analysis software provide meaningful results for the optimal design of components in the development departments.

The integrated solution is used by development departments and after-sales services in the automotive industry especially for mobile applications. This allows real and extreme driving situations to be tested on the road.

For the integrated solution, users need a Vispiron Rotec RASdelta measurement system with speed/analog/temperature/DMS and CAN measurement cards, associated sensors and the analysis software, a Klaric HV breakout box, a Klaric multi-HV and various cables. It will be available from April 2023.

Vispiron Rotec and Klaric will showcase the integrated solution for the first time at Automotive Testing Expo India (April 18-20, 2023 in Chennai) and Automotive Testing Expo Europe (June 13-15, 2023 in Stuttgart, Germany).

About Klaric GmbH & Co.KG

Klaric GmbH & Co. KG, based in Stuttgart, Germany, has specialized in the development of measurement and testing technology for mobile and stationary applications in vehicles or in test benches – mainly in the automotive industry – for 30 years. It is used for precise measurement of currents, voltages and temperatures in a wide range of environments and offers solutions from low voltage to safe measurement in high voltage systems. The application areas of the measurement technology range from hexacopters to e-cars.

Since 1988, Vispiron Rotec, based in Munich, Germany, has been the world market leader for sophisticated measurement technology, analysis software and engineering services for torsional vibration analysis and complex measurement tasks.

The Rotec measuring system is used by measurement engineers for investigations and analyses of (electric) drive trains, gearboxes, turbines and rolling elements. It is used to precisely analyze the causes of acoustic problems and mechanically damaging (torsional) vibrations. It provides engineers with significant results for their product development, damping methods and component design.

Rotec Engineering is an engineering team specialized in consulting and management of complex measurement projects for driveline components and vibroacoustics.

Rotec is present in the Mobility, Power, High Performance Engines, Heavy-duty Engines and Mechanical Engineering sectors.

Vispiron Rotec GmbH

Joseph-Dollinger-Bogen 28

80807 München

Telefon: +49 (89) 32 36 51 0

Telefax: +49 (89) 32365156

http://www.rotec-munich.de

Public Relations

E-Mail: inken.pauli@rotec-munich.de

![]()